The Bruker SMART CCD detector system is used to collect single crystal or powder diffraction data. Many APS users are familiar with this system from their home laboratories, and it is desireable to be able to use the same software to collect data at the APS using any beamline diffractometer and shutter system. However, the SMART software is written specifically to talk to the Bruker General Goniometer Control System (GGCS) motor/shutter controller. Most beamlines require EPICS control of their diffractometer for use with other software (e.g. SPEC), and will not want to install the GGCS hardware for use only with the SMART software.

The GGCS communicates with the PC running SMART via an RS-232 serial interface. The solution which I have developed is to make an EPICS IOC emulate the GGCS, so that the SMART software thinks it is talking to a GGCS, while it is actually communicating with EPICS.

There are two version of the SMART software: the standard Eulerian geometry version, and the Kappa geometry version. This EPICS software should work with either one, but it has only been tested with Kappa SMART so far. The nomenclature of the SNL program, the database and the medm screen assume the Kappa geometry. If the Eulerian version of SMART is used then one should substitute values for the chi motor wherever the kappa motor is referenced.

SMART can control up to 4 diffractometer axes. These are 2-theta, omega, phi and kappa (or chi). This EPICS software will also work with diffractometers with fewer axes, and we have successfully used it to collect data with a simple system with a single rotation stage, which could be called phi or omega.

The EPICS implementation consists of the following:

smartControl.db. This

database contains almost no “logic” with no

links between records in the database. The records are

simply variables which channel access clients and the

State Notation Language (SNL) program use.smartControl.st. This

program implements all of the logic for emulating the

GGCS, controlling EPICS motors and PVs to control the

shutter and detector trigger.smartControl.adl. This

screen is used to configure and monitor the SNL program.The SMART system and the EPICS IOC must be connected as follows:

The following are the comments from the beginning of smartControl.db

which describe the macro parameters which must be supplied in the

dbLoadRecords command in the vxWorks startup script.

# This database works with SNL program smartControl.st to allow SMART to # control EPICS motors # # Mark Rivers # September 17, 2000 # # Macro parameters: # $(P) - PV name prefix # $(R) - PV base record name # $(C) - Card # (0,1,2...) of the board with the IP slot for the # generic serial records # $(IPSLOT) - IP slot (A-D) for the serial I/O module # $(CHAN) - Channel (0-7) for the serial port # $(BAUD) - Baud rate for the serial port # Note: The SMART PC is assumed to be configured with 8 data # bits, 1 stop bit, no parity. # $(FSHUT) - Name of PV to control fast shutter # $(SSHUT) - Name of PV to control slow shutter # $(TRIG) - Name of PV to control detector trigger

$(P) is the prefix for this IOC, for example

13IDC:$(R) is a record base name for this SMART

detector, for example smart1: for the first

SMART detector run through this IOC. $(C),

$(IPSLOT), $(CHAN), $(BAUD)) define the

communications between the SMART PC and the IOC. This

database assumes that the Hideos or MPF server has a name

like a-Serial[0]. If another naming

convention is used then the database will need to be

modified.$(FSHUT) must be the name of an EPICS PV

which closes the fast x-ray shutter when it has the value

1, and opens the shutter when it has the value 0. $(SSHUT) is a similar PV for a slow shutter,

for example a shutter on an x-ray generator. Such

hardware of often not used on a beamline, but the PV must

exist. One should use a soft binary output record or an

unused output of a digital I/O board if there is no slow

shutter hardware. $(TRIG) is the name of an EPICS PV which

controls the TTL trigger input on the CCD controller. It

has the value 0 to turn the detector on, and 1 to turn it

off.The following is an example of the lines which must be put in

the vxWorks startup file to load smartControl.db.

Note that the command line is longer than the vxWorks limit, so

the command must be built using malloc, strcpy

and strcat.

# SMART detector database

str=malloc(256)

strcpy(str,"P=13IDC:,R=smart1,C=0,IPSLOT=a,CHAN=6,BAUD=9600,")

strcat(str,"FSHUT=UnidigBo0,TRIG=UnidigBo1,SSHUT=UnidigBo2")

dbLoadRecords("CARSApp/Db/smartControl.db",str)

After iocInit is called in the startup script the

SNL program must be started. Here is an example:

seq &smartControl, "P=13IDC:,R=smart1,TTH=m29,OMEGA=m27,PHI=m25,KAPPA=m26,SCALER=scaler1,I0=2,stack=10000"

In this command P and R are the same

as that used in loading the database.

TTH, OMEGA, PHI and KAPPA are the

names of the EPICS motors controlling these axes. These motors

are assumed to be in the same IOC that is running the SNL

program, and to be named $(P)mN, for example 13IDC:m29.

SCALER is the name of an EPICS scaler record

which should be used to obtain normalization information for each

frame. I0 is the number of the scaler channel (1, 2,

...) which contains that normalization information. Ideally this

should be an ion chamber mounted downstream of the shutter, so

that it records the integrated beam intensity seen by the sample

during each frame. This information is passed to SMART and is

written in the data files for normalization by SAINT. The scaler

is assumed to be in the same IOC that is running the SNL program,

and to be named $(P)$(SCALER), for example 13IDC:scaler1.

If an Eulerian geometry is being used then set KAPPA

to the name of the EPICS motor controlling chi. If the

diffractometer contains fewer than 4 axes, then set the unused

axes to the same EPICS motor as one of the axes which is used.

The MEDM screen will be used to tell the SNL program not to move

axes which don't exist. For example, if the diffractometer

contains a single axis, phi, which is motor m29 then

the command might look like.

smartControl,P=13IDC:,R=smart1,TTH=m29,OMEGA=m29,PHI=m29,KAPPA=m29,SCALER=scaler1,I0=2,stack=10000"

The source files for smartControl are available in the

ccd application.

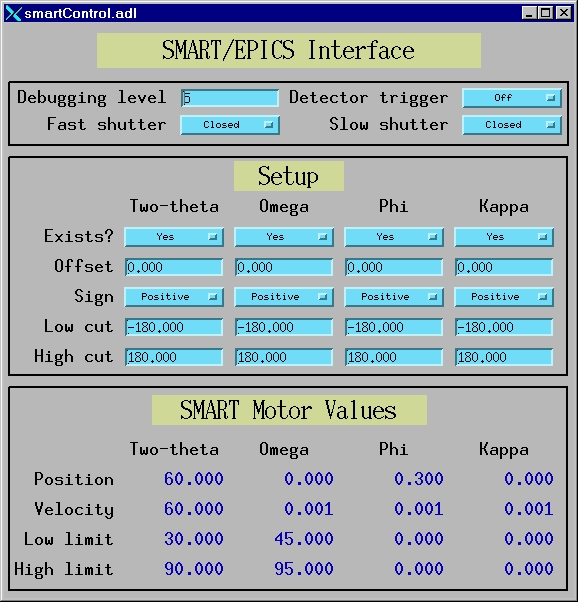

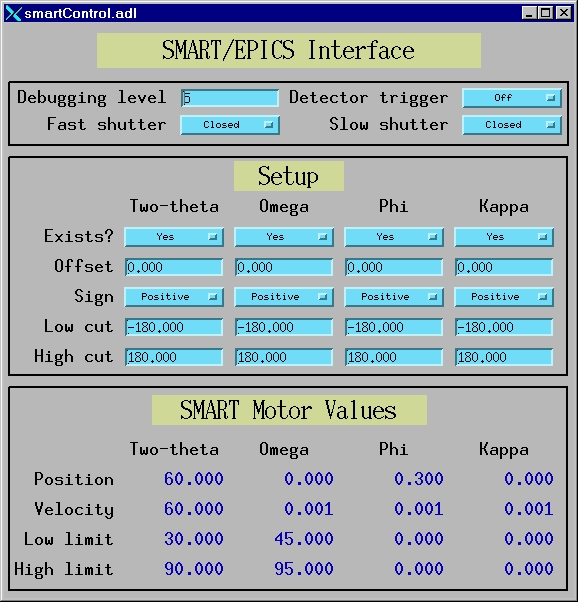

The following shows the MEDM screen (smartControl.adl)

with which the user can view and modify the smartControl

database parameters. smartControl.adl is called with

macro parameters P and R. These are the

prefix and record base used when the database was loaded.

Debugging level is used to control debugging

print statements to the vxWorks console port. The values range

from 0 (no output), 1 (errors and warnings only) through 5

(maximum amount of debugging output). This output can be useful

for seeing what commands are being received from SMART, and the

responses being sent back to SMART. Note, however, that debugging

output reduces the performance of smartControl and

so Debugging level should normally be set to 0.

Detector trigger, Fast shutter and Slow

shutter are used to monitor the state of these control

signals, and also to change them manually if desired.

Under the Setup menu are 5 controls for each

motor.

Exists is a flag which is used to signal

whether or not a given axis actually exists. If an axis

does not exist then smartControl will not

attempt to communicate with that EPICS motor.Offset and Sign are used to

convert from the EPICS motor coordinate system to the

SMART coordinate system. The equation relating the two is

EPICS = Offset + Sign*SMART. If the

coordinate systems are the same then Offset

should be 0 and Sign should be Positive

(1). If the sign convention is different for EPICS and

SMART then Sign should be Negative

(-1).High cut and Low cut are used

to determine when the axis should "roll-over"

by 360 degrees. The relationship, in EPICS motor

coordinates, is:High

cut then the target position is

decremented by 360 degrees. Low cut

then the target position is incremented by 360

degrees.Under the SMART Motor Values screen are 4 values for each motor.

Position is the last position which SMART

commanded this motor to move to. If the motor has never

been told to move by SMART then this value will be 0.Velocity is the last velocity command which

SMART issued for this motor. If the motor has never been

sent a velocity command then this value will be 0.Low limit and High limit are

the last limit values which SMART issued for this motor.The EPICS motor record specifies an acceleration time in

seconds rather than a true acceleration value, for example in

deg/sec/sec. Using a constant acceleration time is not ideal for

oscillation diffraction measurements, since it can lead to

excessively long acceleration times when the oscillation speed is

small. For example, on our Newport diffractometer the phi axis

has a maximum speed of 4 deg/sec, and a maximum acceleration

value of 16 deg/sec/sec. This means that we program the EPICS

motor .VELO field to 4 deg/sec and the .ACCL

field to 0.25 seconds. However, for an oscillation frame in SMART

we might use a 0.2 degree oscillation and 2 second exposure, for

a speed of 0.1 deg/sec. If the acceleration time is unchanged

then the motor will spend 0.5 seconds accelerating and

decelerating, which is 25% of the total exposure time.

Reflections which are in the Bragg condition during these times

will appear too intense. However, it is not necessary to have

such long acceleration times for a 0.1 deg/sec move. Since the

motor can accelerate at 16 deg/sec/sec, the acceleration time can

be reduced to 0.007 seconds.

To minimize the time spent accelerating and decelerating smartControl

does the following:

.VELO

field for each motor is set to the maximum slew speed in

deg/sec, and the .ACCL field is set to the

minimum acceleration time for that slew speed. It

computes the maximum acceleration in deg/sec/sec.

Whenever a motor is moved by SMART the acceleration time

is recomputed using the current velocity to maintain a

constant true acceleration in deg/sec/sec. This leads to

both faster data collection and more accurate

intensities.With the Newport diffractometer and the MM4005 motor

controller there is a global variable drvMM4000ReadbackDelay

which controls the time between when the MM4005 reports that the

motor has stopped moving and when the driver reads the final

position of the motor. This delay is a temporary fix to allow for

the settling times of the DC motors. When using EPICS to

step-scan, for example with SPEC, this value must be set to the

worst-case settling time of any axis. We use a value of 0.5

seconds on our diffractometer. However, when using the

diffractometer with SMART and collecting oscillation data with

the phi axis drvMM4000ReadbackDelay should be set to

0.0. If it is left at 0.5 seconds then each frame will be

collected for an additional 0.5 seconds at the final motor

position, which will clearly lead to incorrect intensities if

there are reflections in the Bragg condition at this point. The

phi axis does not have an on-axis encoder and has a very fast

settling time, so the delay is not necessary.

smartControl does not attempt a complete

emulation of the GGCS. The reason for this is that the GGCS

syntax is very arcane and difficult to parse, and SMART actually

only uses a small subset of the GGCS command set. What has been

done is to emulate all of the GGCS commands that the current

release of SMART actually uses. This leads to a potential problem

when new versions of SMART are released, since they may use

additional GGCS commands. smartControl will need to

be modified to emulate additional GGCS commands if this occurs.

smartControl is limited in the accuracy of the

exposure timing by latencies in EPICS channel access, in the

motor driver and communication, and in the shutter operation. For

each frame the SNL program does the following in response to a

single command line from SMART:

This approach works well if the exposure times are long

compared to the shutter opening time and the latencies between

steps 4-8 above. On APS undulator beamlines exposure times of

less than 1 second are feasible, and the latencies could be a

significant fraction of the exposure time. In general the EPICS

software latencies are very small, because although the SNL

program uses Channel Access, all of the PVs are actually in the

same IOC as the SNL program. The performance of smartControl

is probably very similar to an actual GGCS system, although no

measurements have been made yet to establish the latencies.

In the future smartControl will be enhanced to

use the trajectory scanning and synchronization features of the

MM4005 and OMS-58 motor controllers to improve the accuracy of

the exposure timing. This software will ensure that motor is

actually at the correct speed and position at the instant the

shutter opens and closes. This will require controller-specific

software and hardware.